Our Capabilities

Digital Printing

DTF & DTG Printing

We offer advanced DTF (Direct to Film) and DTG (Direct to Garment) printing solutions, ensuring high-quality, vibrant, and long-lasting prints for all types of fabrics. Whether you need full-color designs, intricate details, or soft-feel prints, our cutting-edge technology guarantees precision and durability.

- High-Resolution Prints – Crisp, detailed, and vibrant colors with no cracking or fading

- Versatile Fabric Compatibility – Works on cotton, polyester, blends, and more.

- Soft & Breathable Feel – No thick layers, maintaining fabric comfort.

- Eco-Friendly Inks – Water-based inks ensure safety and sustainability.

- No Minimum Order Quantity – Ideal for both bulk and small-scale custom orders.

- Wash Durability – Prints withstand multiple washes without deterioration.

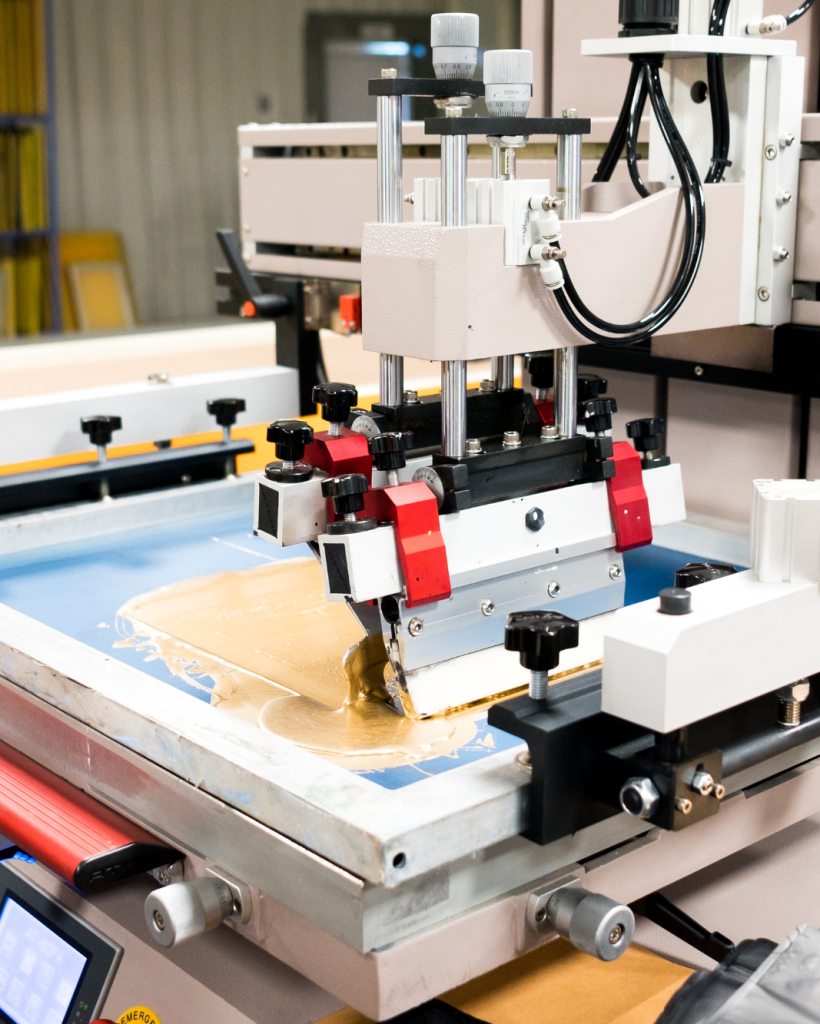

Screen Printing

Our Screen Printing process delivers bold, durable, and high-quality prints, making it the ideal choice for bulk production and long-lasting designs. Whether you need vibrant graphics, solid color prints, or special ink effects, our expertise ensures the best results.

- Long-Lasting Prints – High durability withstanding repeated washes.

- Bold & Vibrant Colors – Rich, opaque, and long-lasting ink application.

- Cost-Effective for Bulk Orders – Perfect for large-scale production.

- Versatile Applications – Works on cotton, polyester, blends, and various fabrics.

- Special Ink Effects – Metallic, puff, glow-in-the-dark, reflective, and more.

- Eco-Friendly & Non-Toxic Inks – Ensuring safety and sustainability.

Water-Based Ink Screen Print

Water-based screen printing is perfect for light-colored fabrics as the ink absorbs into the fibers, creating a soft, breathable finish. Unlike plastisol, it feels weightless and enhances fabric texture. Plus, it's eco-friendly and ideal for high-quality apparel.

Plastisol-Based Ink Screen Print

Plastisol screen printing is great for dark-colored fabrics as the ink stays on the surface, creating a bold, opaque finish. Unlike water-based inks, it adds a thicker feel and a slight texture. Plus, it’s durable and perfect for vibrant designs.

Pulling Printing

Hand-painted paste printing works well on dark fabrics, forming a vivid, solid coat that sits on top. Unlike dye-based methods, it leaves a rich texture and a thicker feel. Plus, it lasts long and enhances bold patterns.

Crack Printing

Heat-reactive crackle printing uses a special paste that contracts under high temperatures, forming a unique cracked texture on the fabric. After application and drying, the surface develops an organic, aged effect, adding depth and character to the design. Plus, it enhances vintage and artistic styles.

Puff Printing

Thermal-expanding puff printing uses a special paste that swells under heat, creating a bold, three-dimensional texture on fabric. Once printed and dried, it forms a soft, elevated effect that adds depth and dimension. Plus, it’s perfect for eye-catching, tactile designs with a unique feel.

Thick Plate Printing

High-relief thick plate printing uses a custom-designed plate that applies an enhanced ink layer, creating a striking, raised effect on fabric. This method ensures a deep, prominent finish that stands out with bold definition. Plus, it adds durability and a premium feel to the design.

Embroidery

Types of Embroidery

Embroidery techniques include directly stitching designs onto fabric with thread or attaching pre-embroidered elements to garments.The cost increases with the embroidery’s size and complexity, as more stitching requires additional time and materials.Moreover, heavy embroidery is not ideal for lightweight fabrics with a low GSM, as it may affect durability and comfort.

Applique Embroidery

3D Embroidery

Toothbrush Embroidery

Flat Embroidery

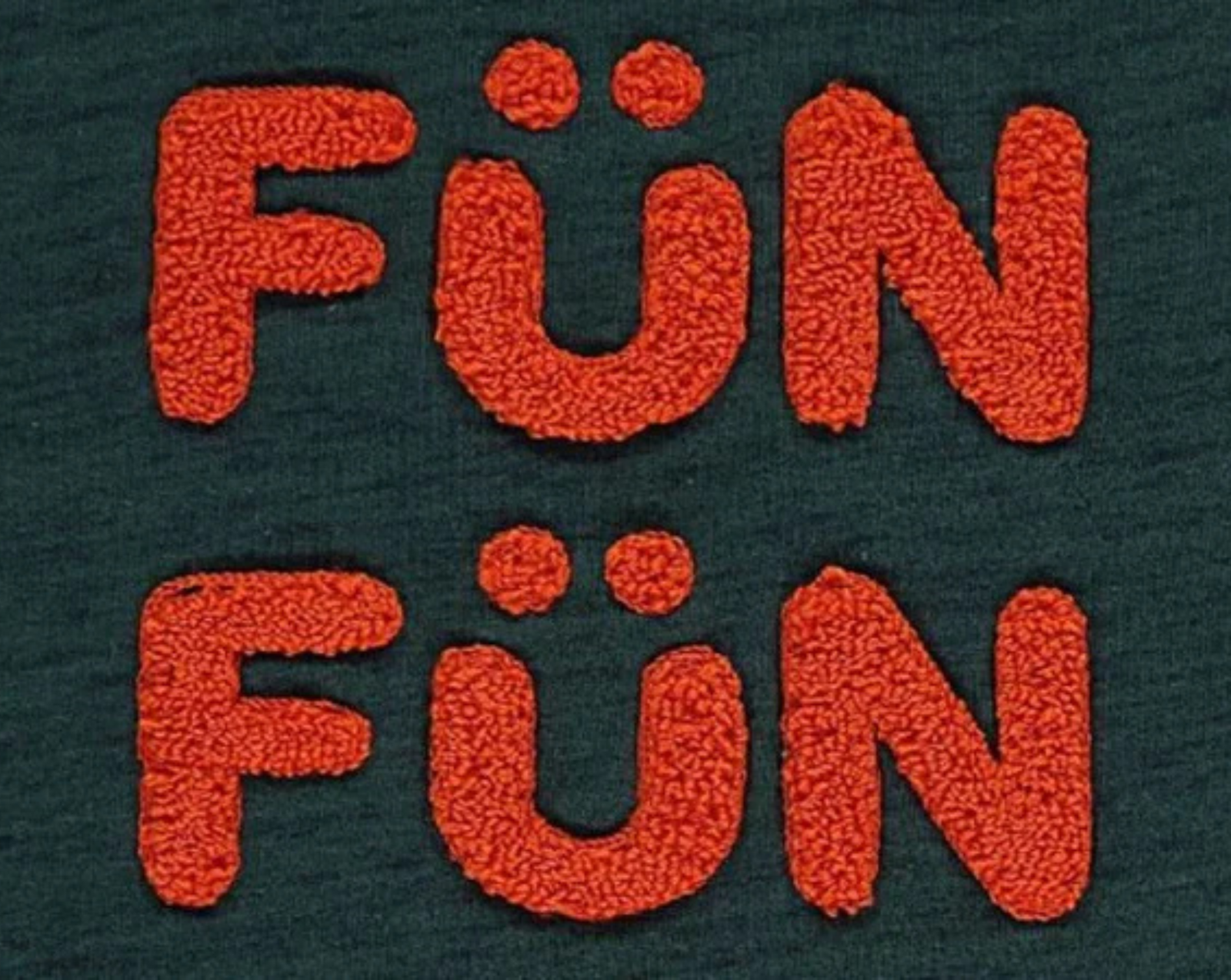

Towel Embroidery

Embroidery Patch

Heat Transfer Printing

Heat transfer printing is a technique where designs are first printed onto special transfer paper or vinyl and then applied to fabric using heat and pressure. This method ensures a precise and detailed finish, making it ideal for complex patterns and full-color graphics.

One of its key advantages is the ability to achieve vibrant colors and intricate designs at a relatively lower cost, especially for small-batch production or custom prints. It also allows for quick application without the need for extensive screen setups.

However, heat transfer prints can have a slightly plastic-like feel and may not be as breathable as other printing methods. Over time, repeated washing or stretching may affect their durability, so proper care is essential to maintain their quality.

Effects

Washing Effect

The washing process aims to achieve a vintage or distressed appearance to clothing. Spraying a special effects agents solution onto specific areas achieves localized fading, while immersing the entire garment in a mixture of special effects agents solution, sand (and stones), and agitating it results in overall fading with unique patterns.

Snow Wash

Sand Wash

Sun Fade

Others

Other Customizations

High-frequency Printing

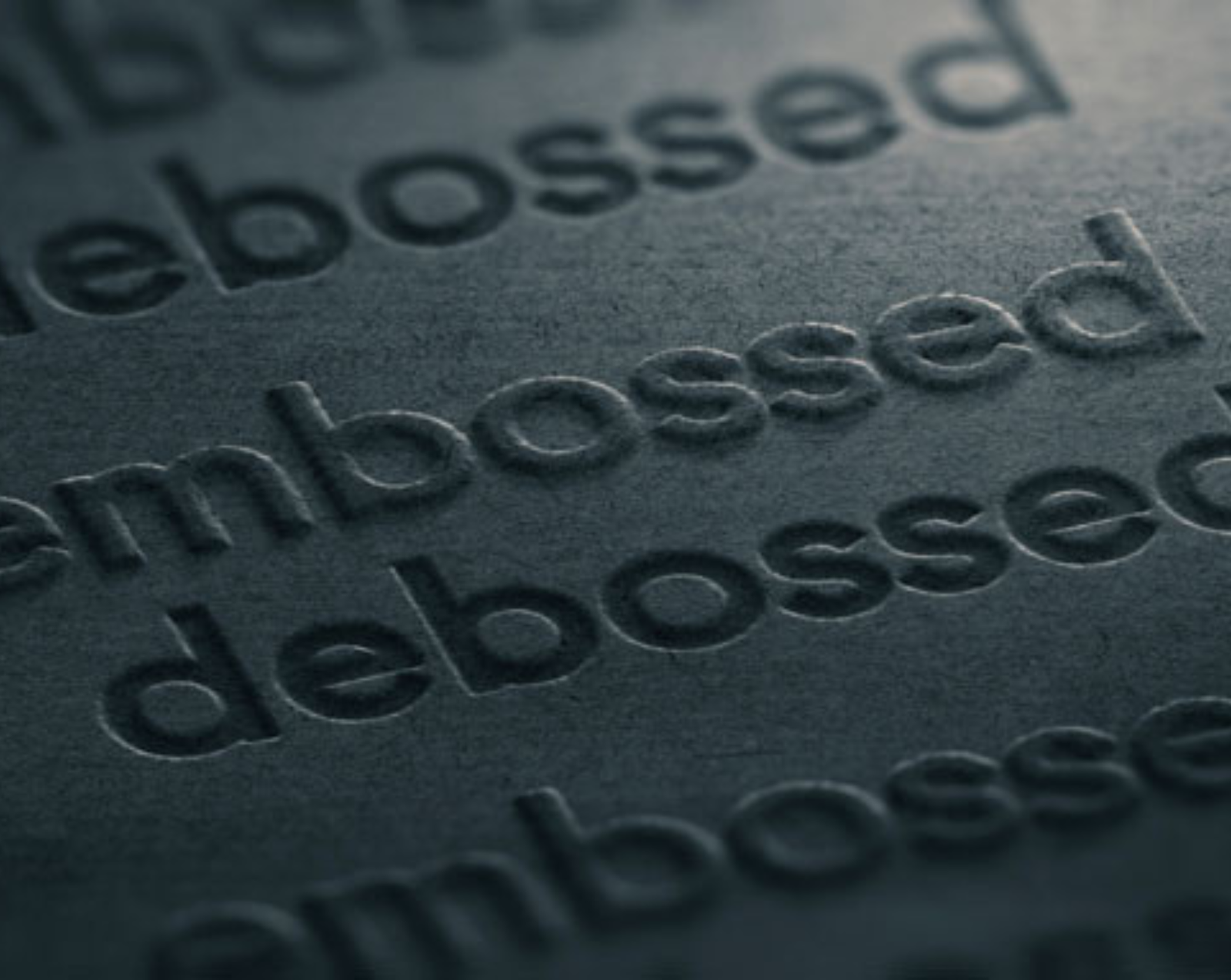

Embossed Printing

Flock Printing

Rubber Printing

Hotfix Rhinestone